No two jobs are similar. Customer needs differ from site to site and the constraints that they have to operate in vary. Physical constraints – safety of operators, sub sea decommissioning radioactive contaminant etc. would restrict / hamper the smooth execution of the project. This is where siegenthalerconsulting GmbH expertise comes in. Be it in the design & development of system solution or enhancement of an existing system, the process of understanding the issues /constraints faced and coming up with a project-based solution is what we strive towards.

Below you will find various projects to the success of which the employees of siegenthalerconsulting GmbH have made a significant contribution.

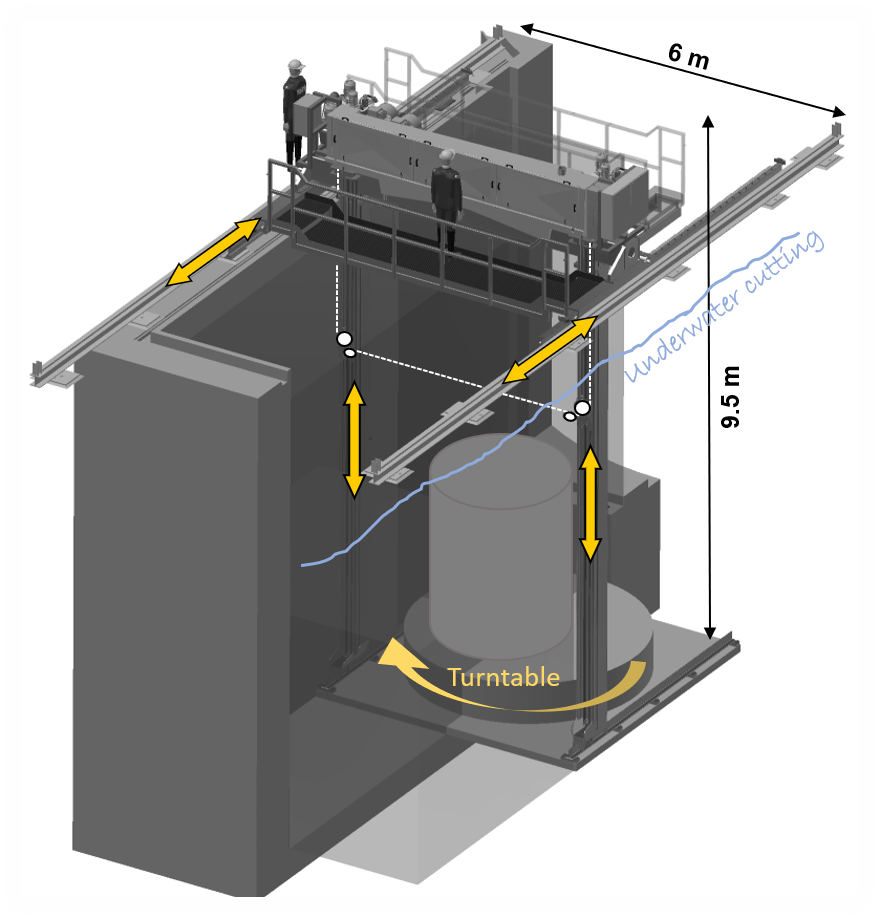

Stationary Portal Diamond Wire Saw Sytem for NPP Decommissioning

- Vertical and horizontal cutting possible

- Designed for high diamond wire tension

- Guided on rails above and below

- Infinitely adjustable and load-dependent advance feed speed

- Closed diamond wire loop (no wire connector necessary)

- Underwater sawing

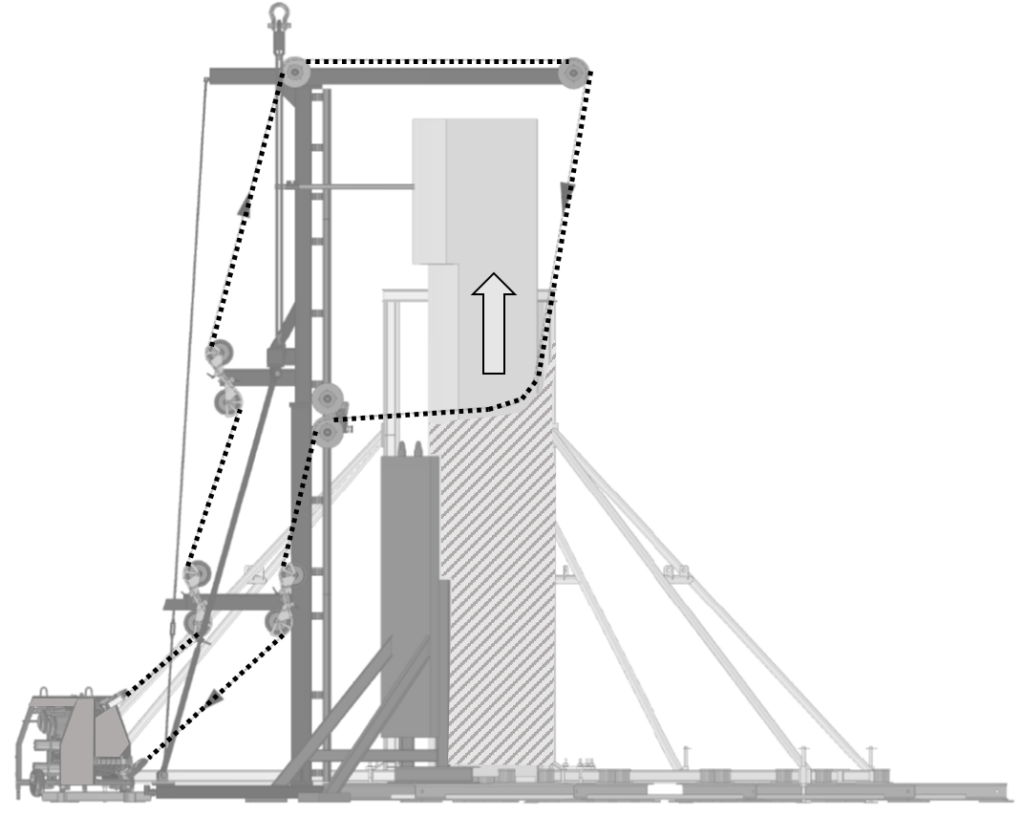

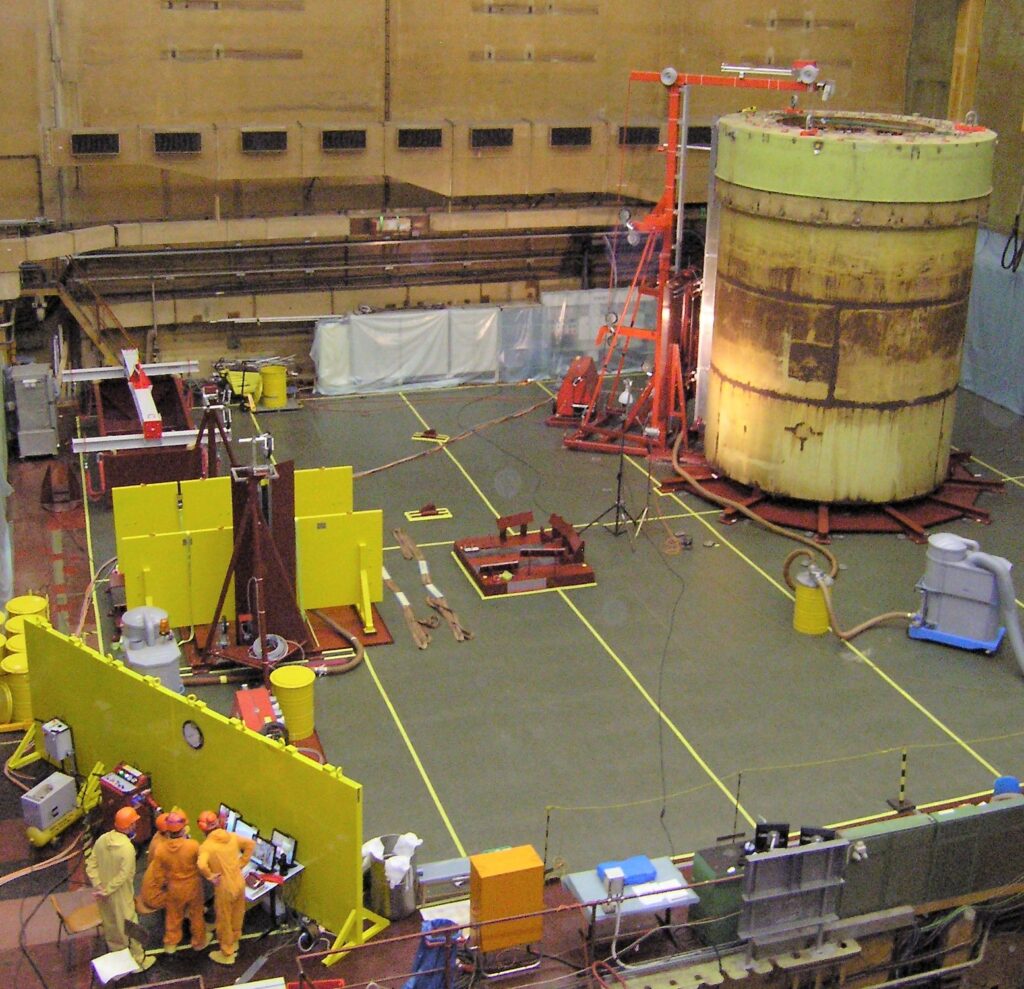

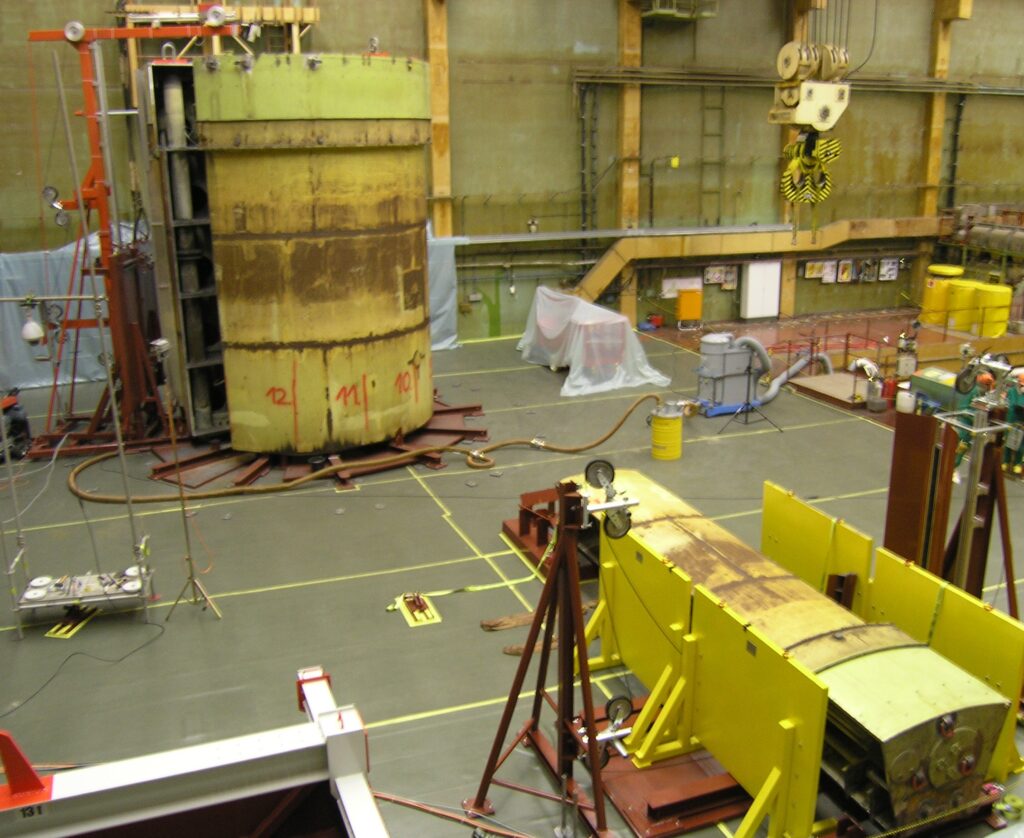

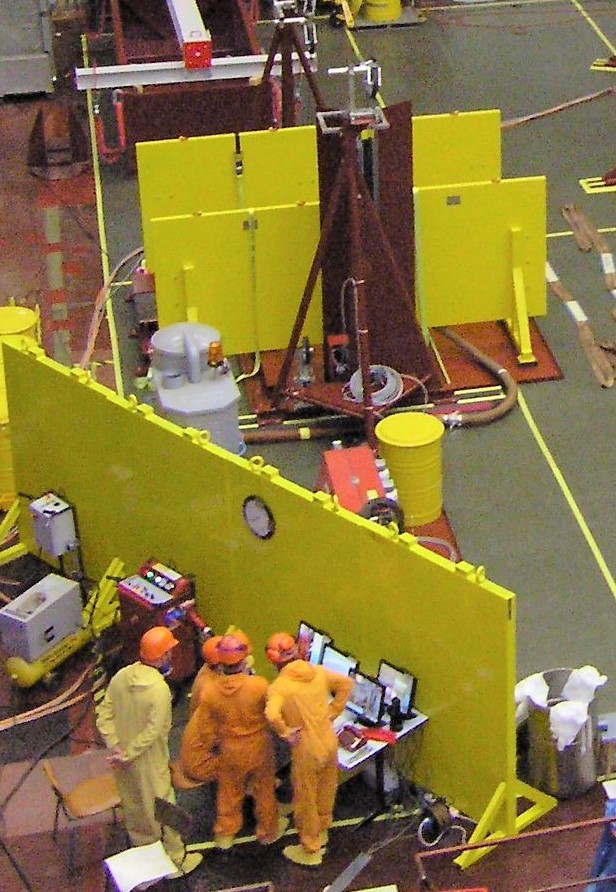

Gallows Diamond Wire Saw System for NPP Decommissioning

- Remote-controlled gallows diamond wire saw system

- The diamond wire is driven by a standard diamond wire saw drive unit

- The sawing advance feed is controlled remotely via the control panel of the drive unit

- Dry diamond wire sawing in pure steel without additional cooling

- An 8 m high cooling cylinder of a reactor is sawn vertically into 12 segments

- The 8 m long segments are cut into 1 m long pieces with a mobile diamond portal wire saw

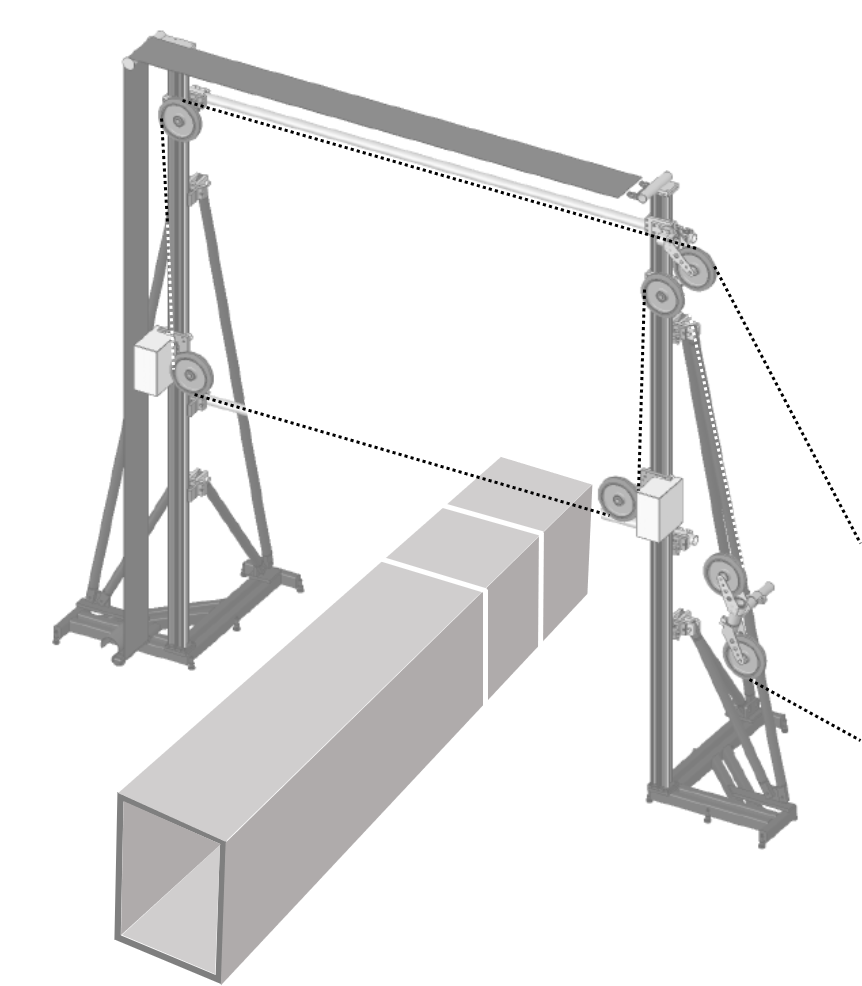

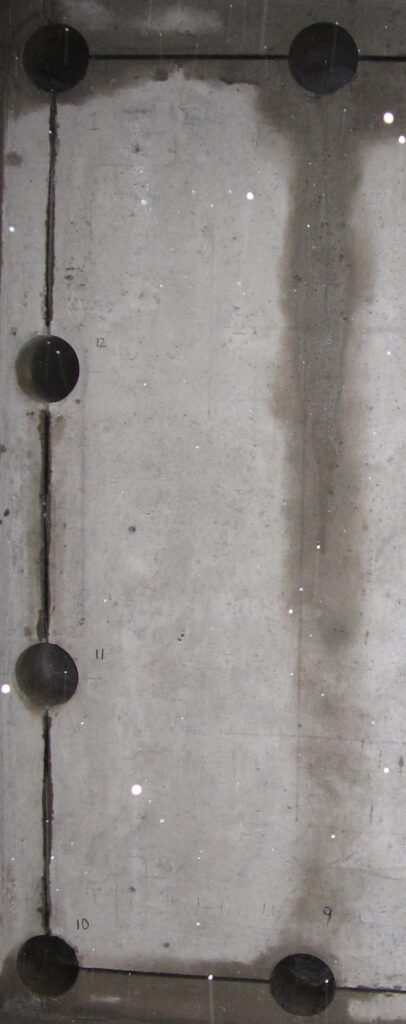

Portal Diamond Wire Saw System for NPP Decommissioning

- Vertical sawing through a concrete container filled with radioactive waste

- The portal wire saw can be swiveled back hydraulically

- Dry diamond wire application

- The sawdust is extracted through a filter system

- The diamond wire is driven by a standard diamond wire saw drive unit

- Closed diamond wire loop (no wire connector necessary)

- The sawing advance feed is controlled remotely via the control panel of the drive unit

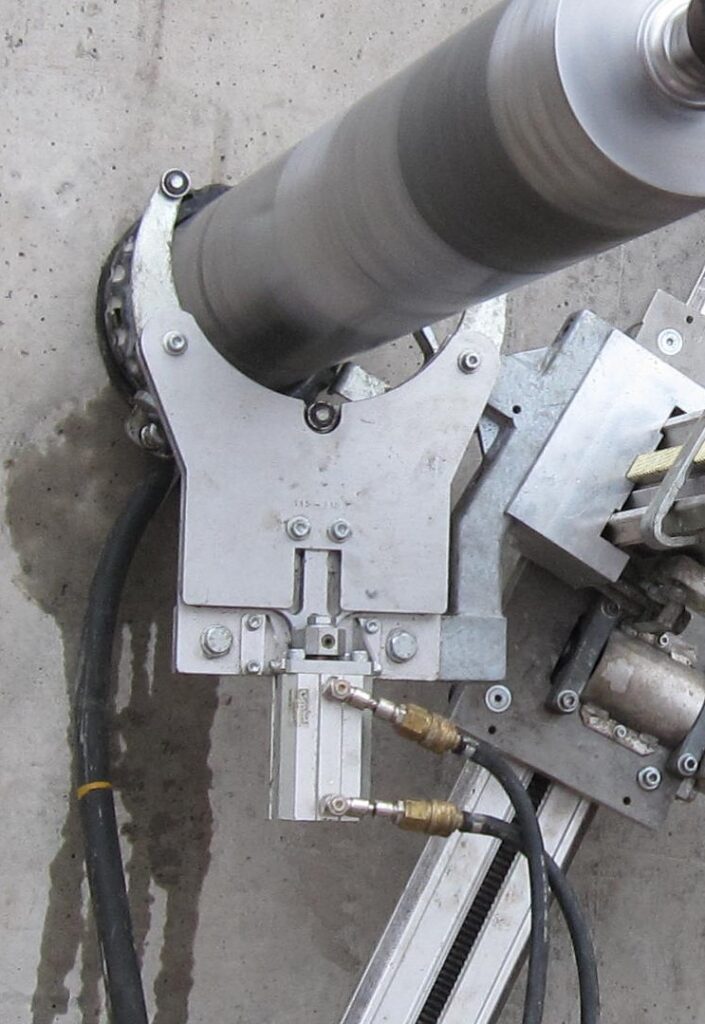

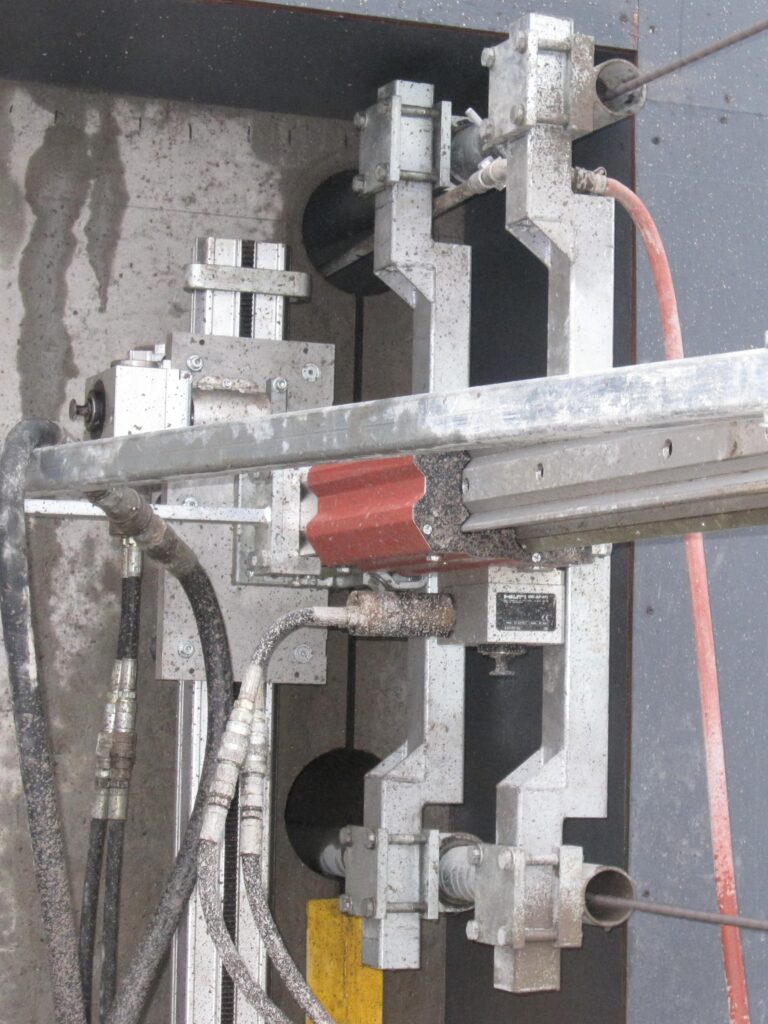

Remote-controlled hydraulic Plunge Diamond Wire Saw and hydraulic Diamond Core Drilling System

- 1. Remote controlled hydraulic diamond core drilling system

- 2. Remote controlled hydraulic plunge diamond wire saw system

- The diamond wire is driven by a standard diamond wire saw drive unit

- Creation of a recessed opening in a hot cell in a nuclear power plant

Remote-controlled drilling machine in the decommissioning of a nuclear power plant

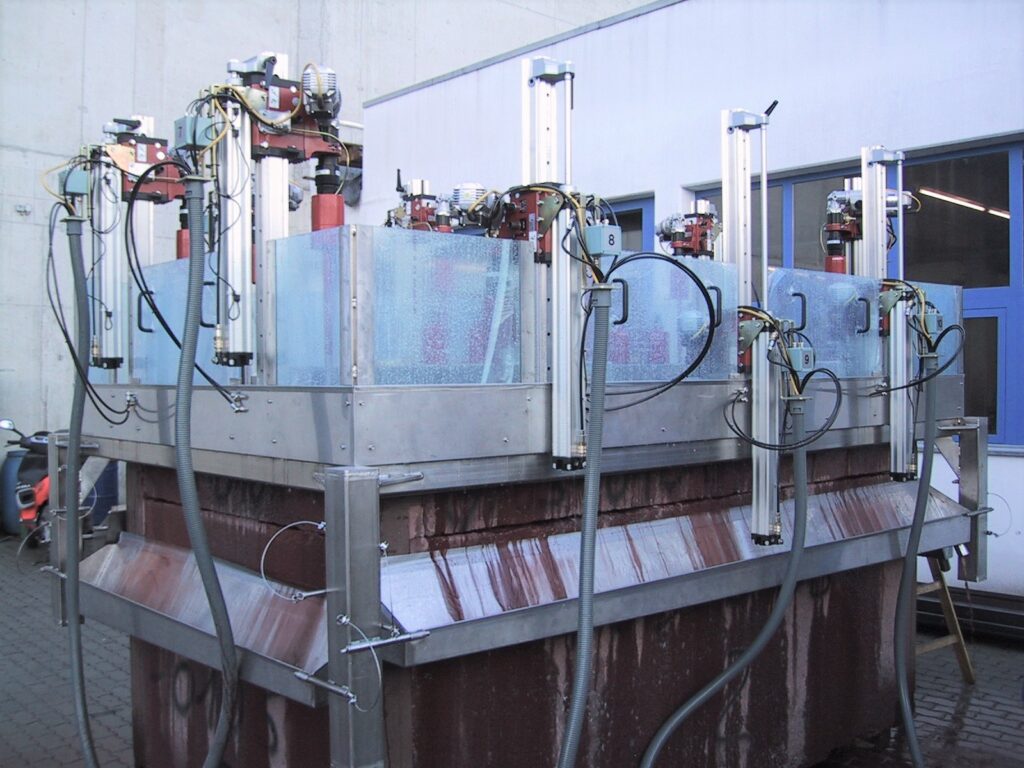

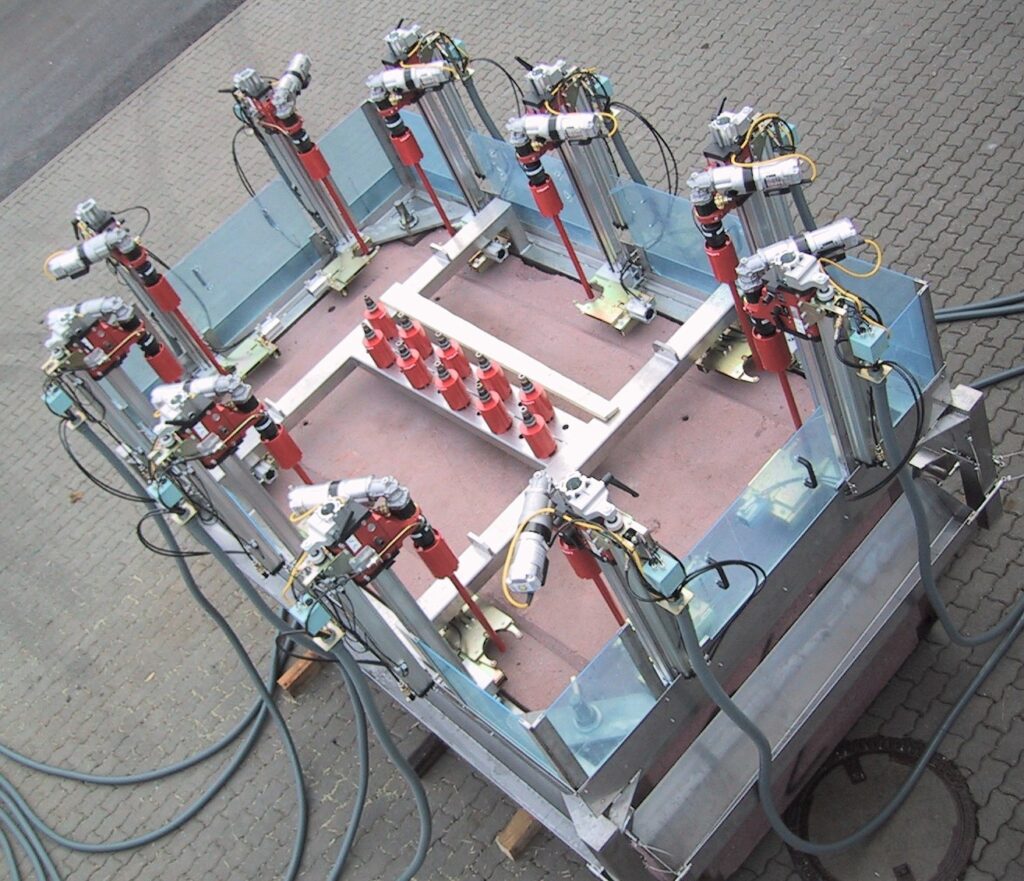

- For a safe transport of the concrete containers filled with radioactive waste, the concrete covers must be screwed on additionally.

- 10 diamond core holes with 2 different diameters can be drilled simultaneously

- The electrical core drilling machines are operated remotely from a control panel

- Pneumatic drill feed

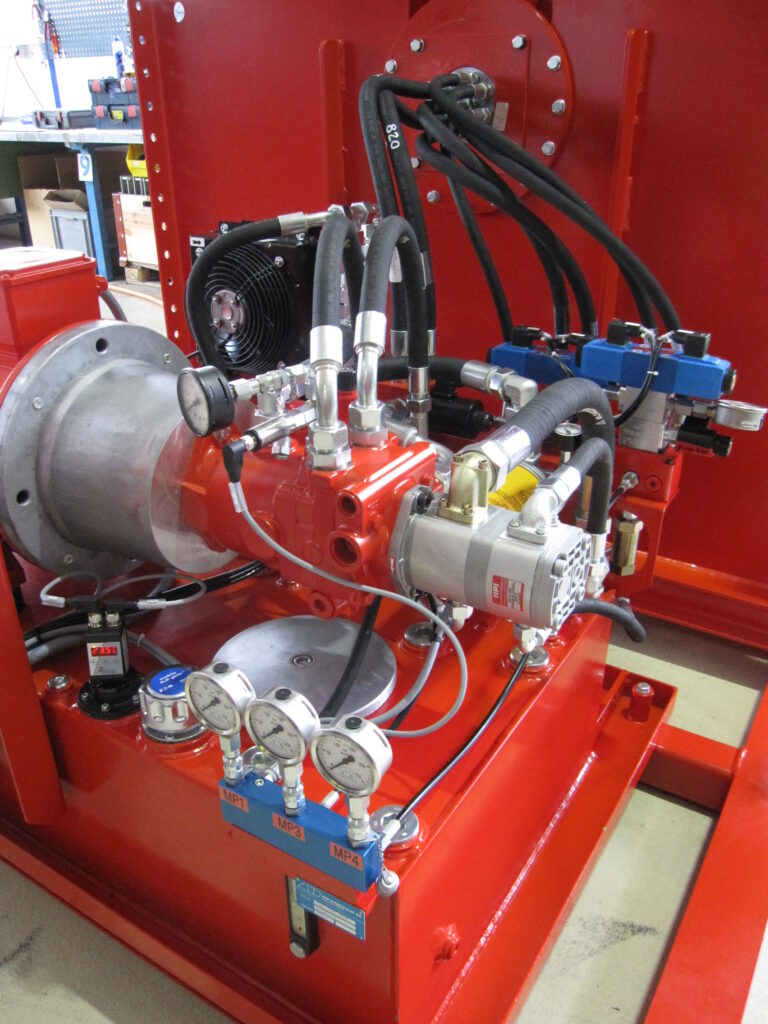

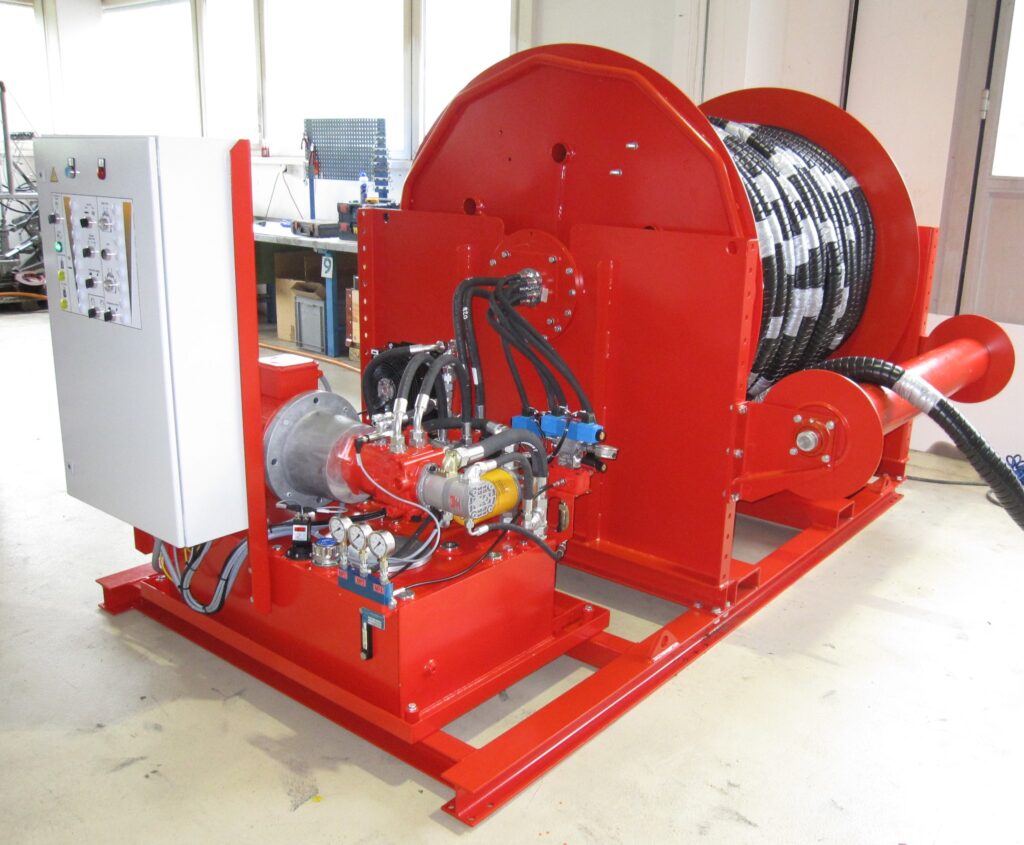

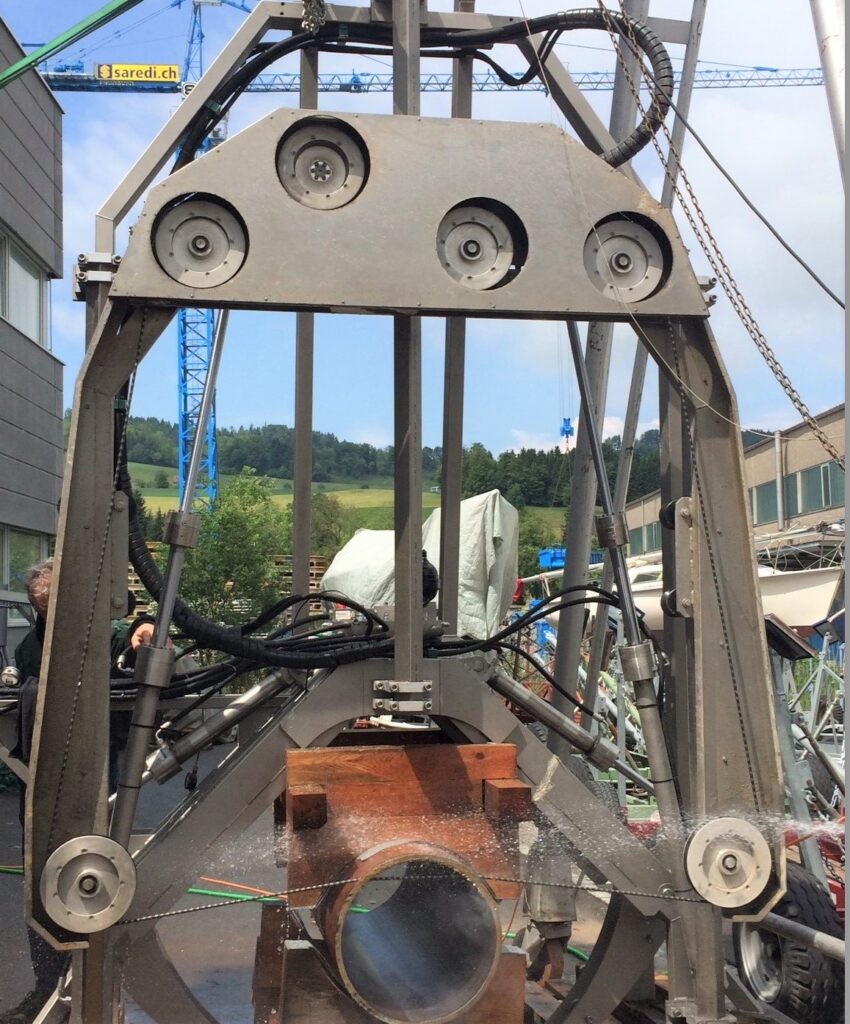

Offshore: Hydraulic underwater Pipe-Cutting Wire Saw System

- Underwater pipe cutting wire saw for diameter range 36 - 60 inches (950 - 1500 mm)

- Diamond wire drive motor: Hydraulic

- Diamond wire peripheral speed: Infinitely adjustable 0 - 30 m/s

- Length of the hydraulic hoses: 130 m

- The hydraulic hose coil is equipped with a hydraulic drive

- The complete pipe cutting wire saw and the hydraulic cylinders are made of stainless steel

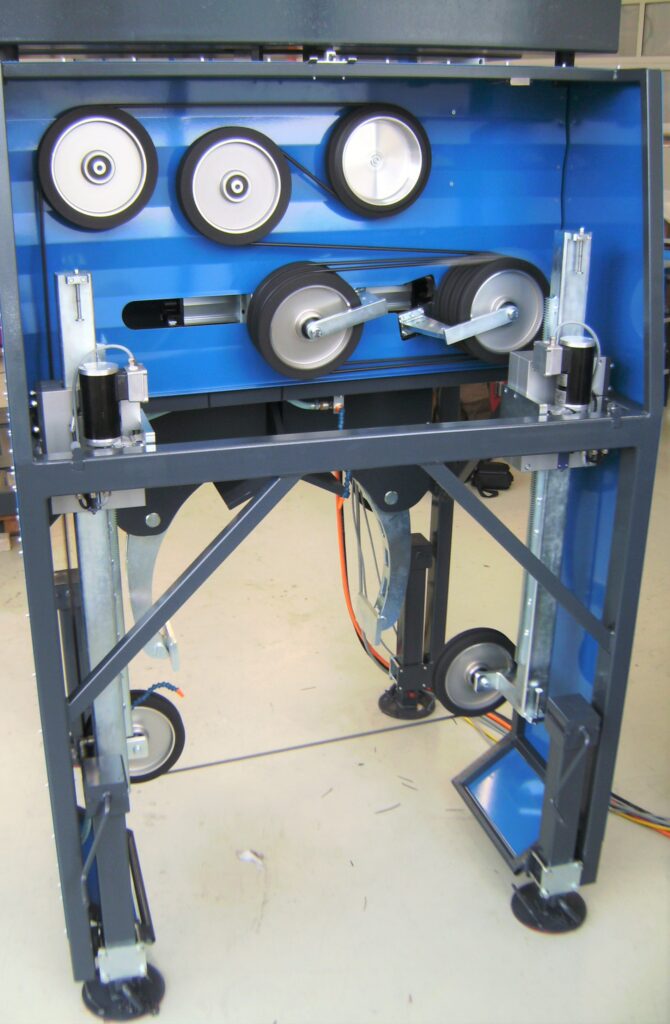

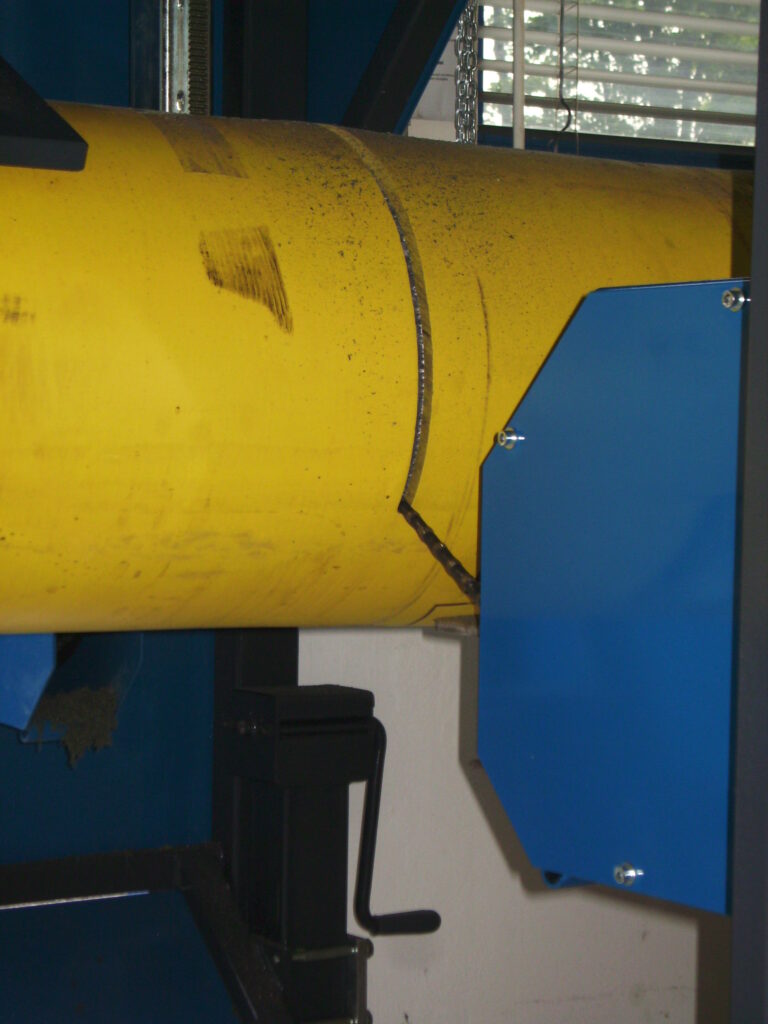

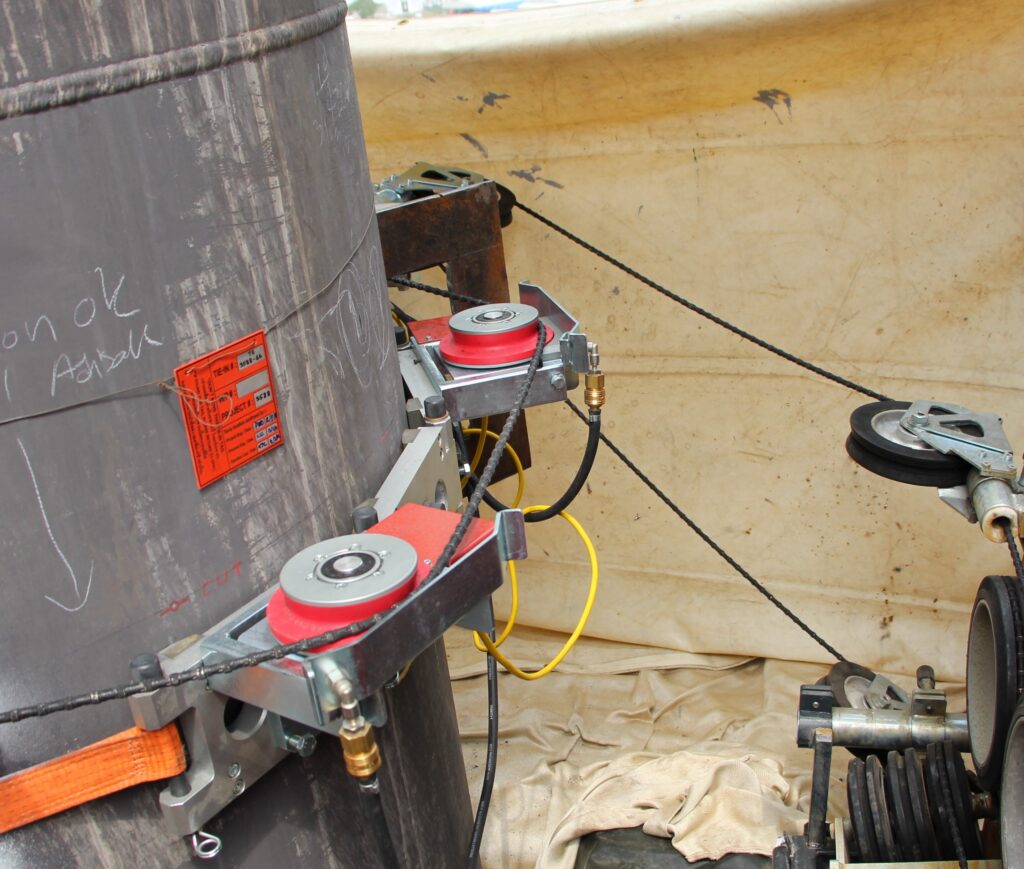

Onshore: Pipe-Cutting Wire Saw System for pipelines

- Electrical Pipe-Cutting Wire Saw System

- Pipe diameter range: 10 – 24 inches (250 - 600 mm)

- Pneumatical diamond wire tensioning system

- Diamond wire peripheral speed: Infinitely adjustable from 0 - 27 m/s

- All functions are controlled remotely from a control panel

- The height of the pipe cutting wire saw system and its inclination can be adjusted

- The pipes are held in position with a hydraulic clamp

Onshore: Remote operated Mobile hydraulic Pipe-Cutting Wire Saw System

- Mobile hydraulic pipe wire saw with a pipe diameter range of 16 - 28 inches (400 - 700 mm)

- The machine is held in position with a hydraulic clamp

- Pneumatical diamond wire tensioning system

- Diamond wire peripheral speed: Infinitely adjustable from 0 - 20 m/s

- Hydraulic hose length: 50 m

- All functions are controlled remotely from a control panel

Onshore: Pipe Sawing Attachments in a Petroleum Refinery

- Pipe sawing attachments

- Precisely controllable saw cut

- Pipe diameter range: 20 – 60 inches (500 – 1500 mm)

- Remote controlled, electrically disengageable diamond wire guide pulleys

- The diamond wire is driven by a standard diamond wire saw drive unit